flame lamination

- flame bonding brilliance -

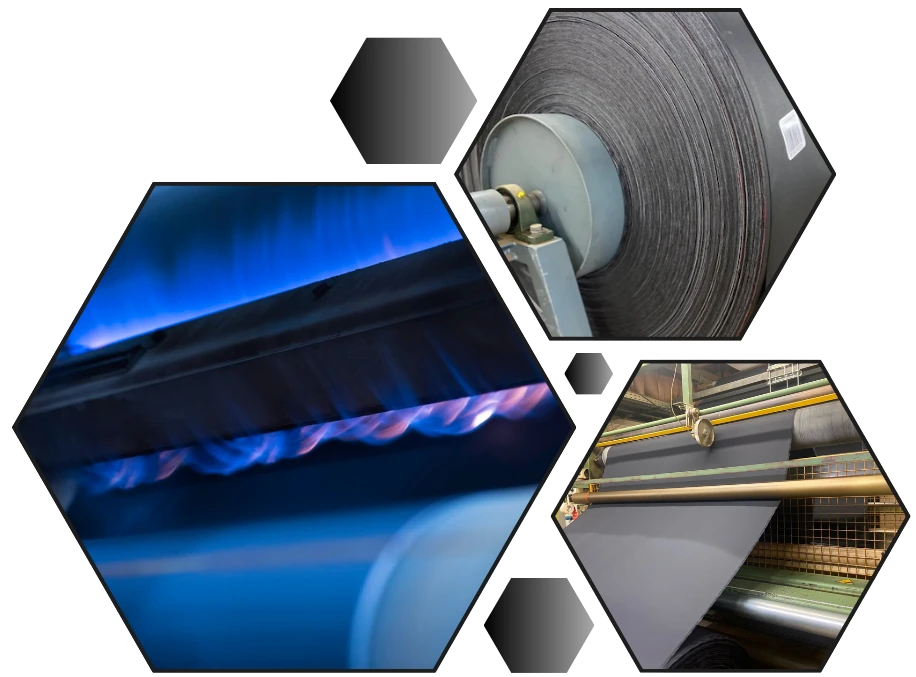

This technique involves exposing foam to an open flame on one or both sides, producing a thin, almost invisible adhesive coating. This process is essential for a variety of applications in various sectors.

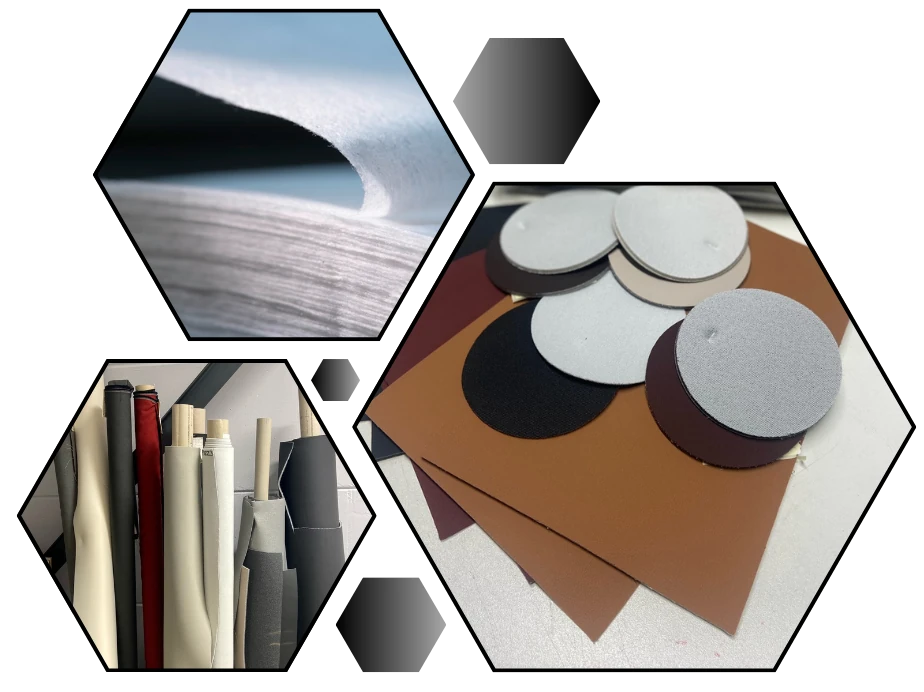

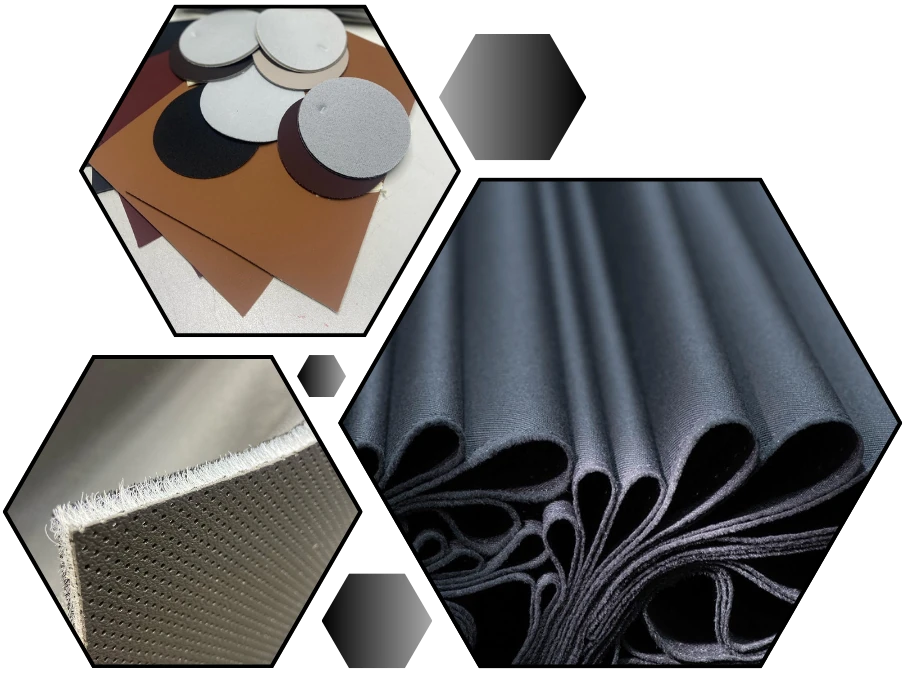

Thanks to our advanced technology, we can handle a variety of materials, including different textiles, synthetic leather, nonwovens, aluminum and fiberglass. This adaptability offers a wide range of options for custom solutions.

Our modern flame lamination lines can handle material widths up to 300 cm and can produce multilayer composites with thicknesses up to 20 mm. These continuous processes are designed for maximum efficiency, minimizing production downtime and general scrap costs.

Working closely with our customers, we create tailored solutions. Depending on the decorative surface material, we can offer a continous distortion determination during the lamination. Our standard processes include inline thickness measurements and camera-based inspections for irregularities in the backing lamination. This ensures 200% inspection of the material—visually on the front and camera-assisted on the back—guaranteeing the highest quality.